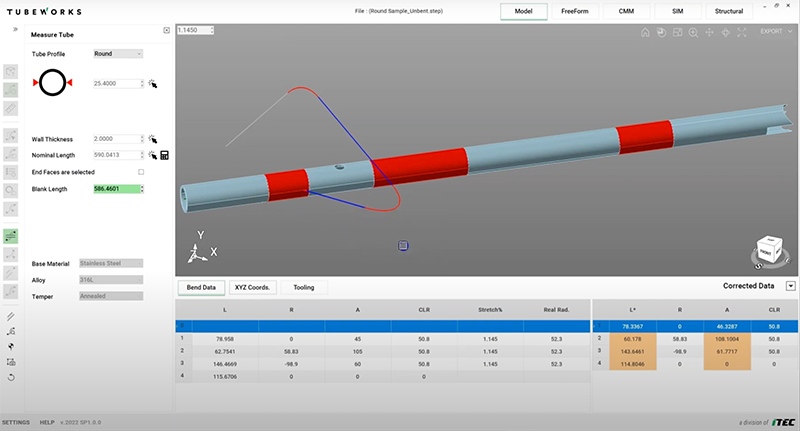

TubeWorks

Pro

Whether creating new tube designs or correcting existing ones, TubeWorks excels at automating model geometry creation, importing and processing multiple file formats for accurate quoting, and correcting poorly modeled geometries—all within a universal and user-friendly interface. Invest in TubeWorks Pro to streamline your tube bending processes and enhance productivity.

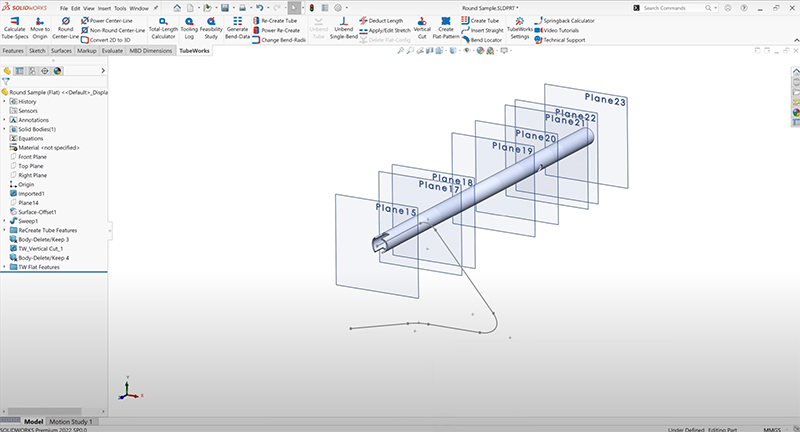

TubeWorks

For SOLIDWORKS

Experience the power of TubeWorks seamlessly integrated into SOLIDWORKS. Enjoy access to all TubeWorks PRO features directly within your SOLIDWORKS environment. Whether creating new tube designs or correcting existing ones, TubeWorks enhances productivity and simplifies tube bending processes with its robust SOLIDWORKS integration.

Boost your

productivity

today!

Discover how TubeWorks tube bending software delivers faster production, reduces waste, and enhances quality control, ensuring a rapid return on your investment. If you’re not satisfied, return the product within 30 days for a full refund.

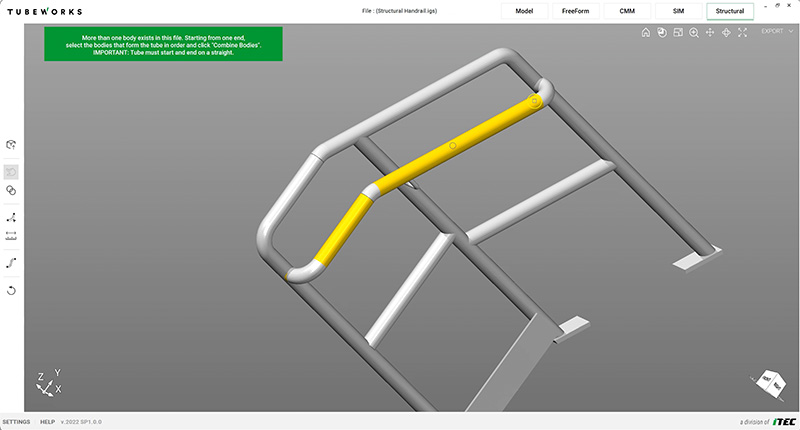

Structural Module

The Structural module in TubeWorks automates analysis and conversion of 3D structural part files from Tekla and SDS2. It streamlines workflows, ensures accurate quoting, and boosts overall efficiency, allowing users to focus on production optimization and meeting project deadlines.

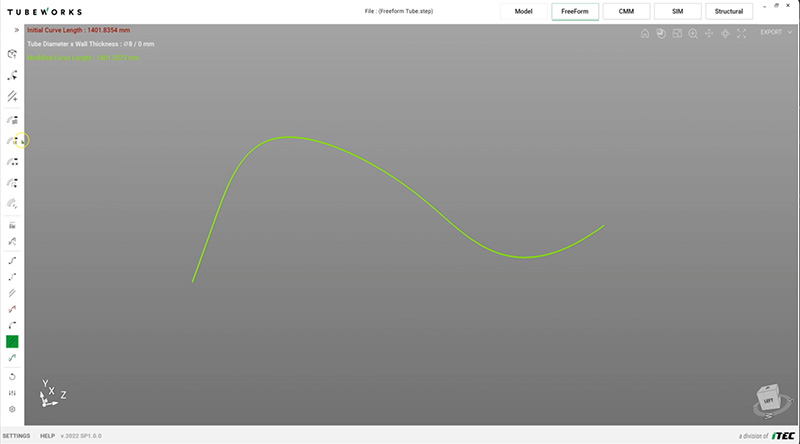

Freeform Module

The Freeform module in TubeWorks simplifies manufacturing by transforming complex 3D geometries into standard LRA data. It enables efficient production of unique designs without specialized equipment, streamlining workflows and enhancing innovation.

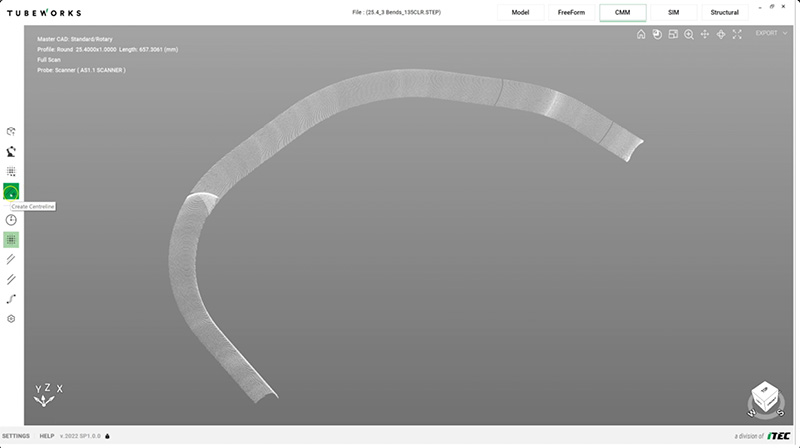

CMM Module

The CMM module in TubeWorks provides detailed measurement and analysis for bent tubes. It ensures accuracy, reduces rework, and maintains high-quality standards throughout production. By integrating this module, users streamline operations and enhance overall efficiency.

Simulation Module

TubeWorks’ machine simulation lets you visualize and validate tube bending processes virtually. It prevents errors, optimizes efficiency, and ensures smooth operations by identifying issues early. This feature reduces setup time and material waste, boosting manufacturing efficiency reliably.

Have any questions?

Connect with Us for Any Questions or Requests! Our Team is Here to Help.

For support related inquiries please email: support@tubeworkssoftware.com

For sales and billing related inquiries please email: sales@tubeworkssoftware.com